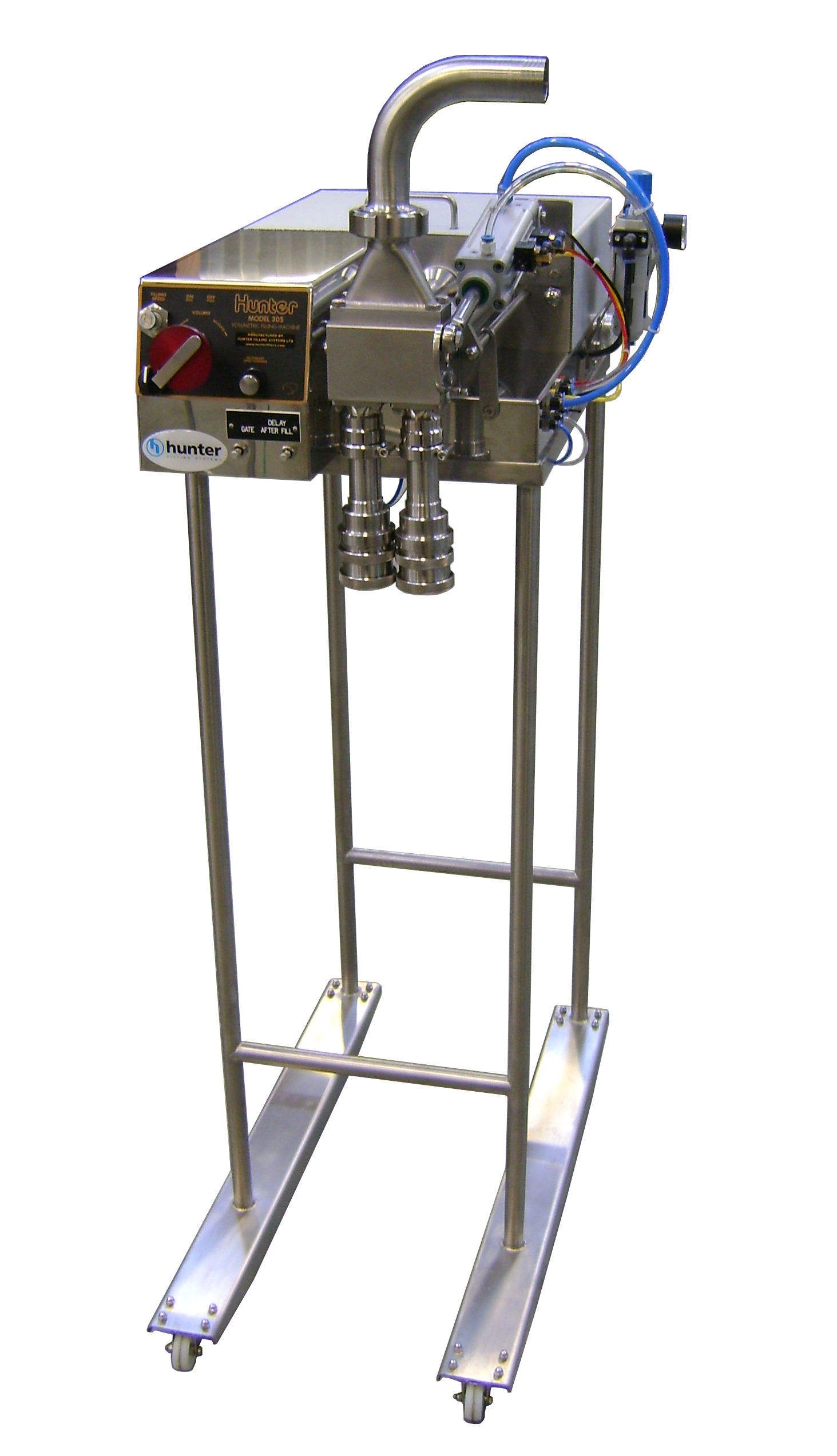

Volumetric Piston Filler - Series 300

Resources

The Series 300 machines are versatile single or multiple head pneumatically operated volumetric (piston type) fillers for accurate dispensing of liquid and semi-liquid products.

Fills of 5ml to 2.5 litres per shot can be achieved using a range of precision-bored heavy wall metering cylinders - an optional multiple stroke mechanism is available for larger fills.

Related Equipment

- Conveyors

- Rotary Tables

- Cap Tighteners

- Container Indexing Equipment

- Interface mechanism to integrate with other equipment

- Labellers

- Induction Sealing

Features

- Available as a single nozzle (Model 305) or in multiple nozzle versions (Model 325, 335, 345).

- Volume range of 5ml to 2500ml, with 5 metering cylinder options.

- Versatile design using pneumatic controls with foot switch or electrical initiation.

- Optional multiple stroke facility for larger fills.

- Product supply to the filler via 27 or 50 litre conical hoppers or suction hose.

- 3 types of product valve available - standard rotary, large rotary and check valve.

- A wide range of non-drip shut off nozzles are available with different outlets.

- Optional sub surface filling mechanism and nozzle for filling foaming products.

- Can be set up as manual or fully automatic with container indexing.

- A range of portable stands, low level, standard and heavy duty with adjustable height.